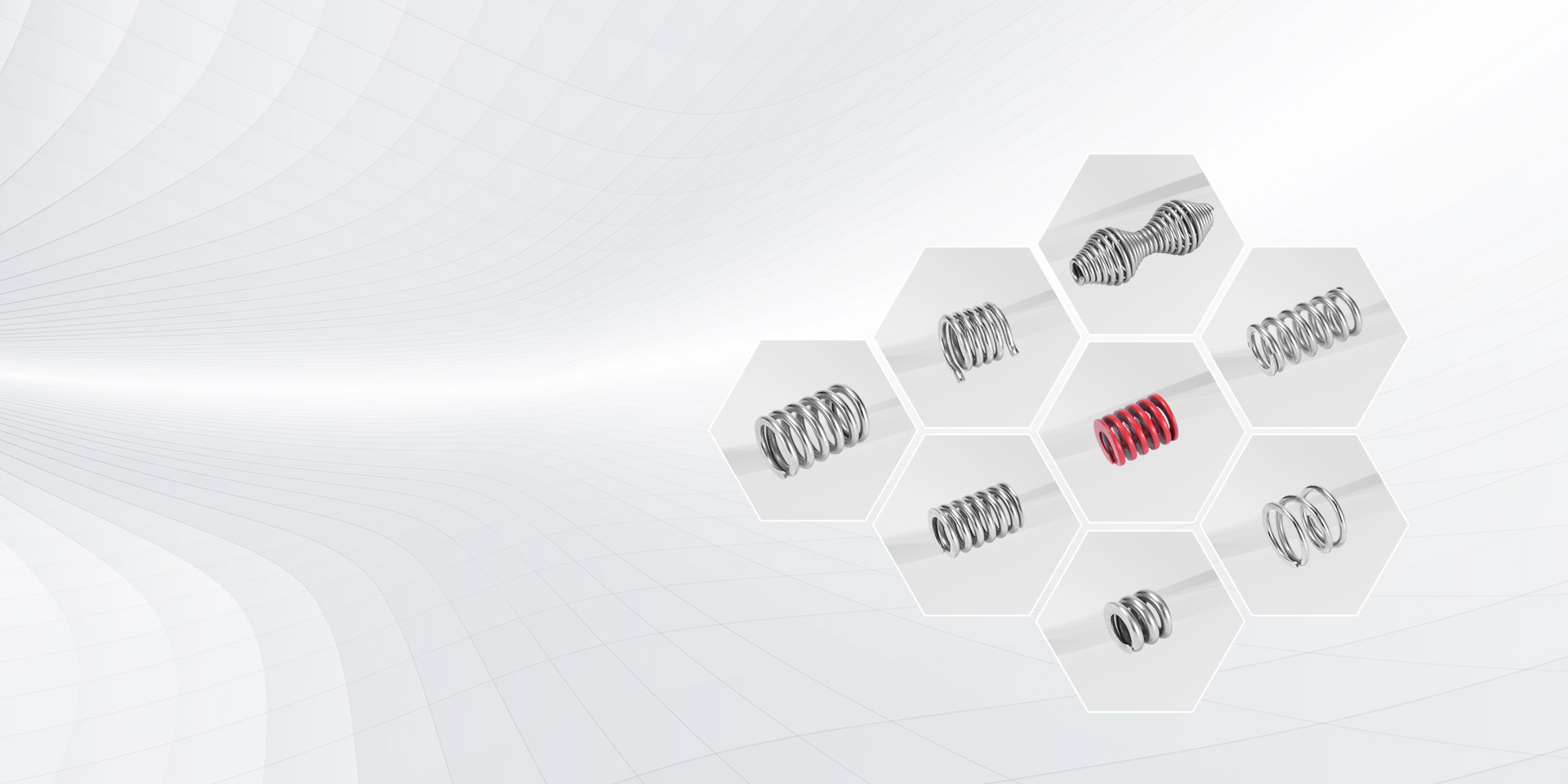

What We Do

Over 40 years of spring manufacturing experience

Always adhere to the pursuit of quality, the persistence of service, and the continuous exploration of innovation. Currently, the company owns more than 90 professional manufacturing equipments and more than 60 testing equipments, enabling us to deliver high-quality products.

Who We Are

Satte Precision Metal (Suzhou) Co., Ltd.

Satte Precision Metal (Suzhou) Co., Ltd. is a Sino-Japanese joint venture with over 40 years of experience in spring manufacturing from its Japanese parent company. Established in December 2013, our company has always adhered to the pursuit of quality, the persistence of service, and the continuous exploration of innovation. Currently, the company owns more than 90 professional manufacturing equipments and more than 60 testing equipments, enabling us to deliver high-quality products. Our company is also one of the world's most precise spring manufacturers (wire diameter 0.009mm, equivalent to 1/5 of a human hair).

Whether it is product consultation, technical support or after-sales service, we will wholeheartedly provide you with professional and timely assistance. At the same time, we also look forward to working with more partners to make progress together and create a better future.

Company Founded in

Over 40 years of spring manufacturing experience

More than 100 professional manufacturing equipments

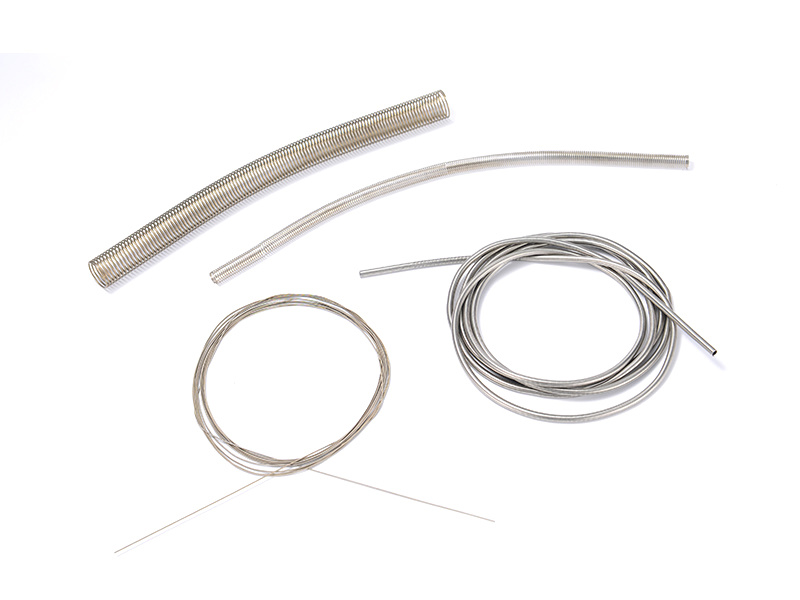

Smallest spring, wire diameter 0.009mm

Our Advantages

World's smallest spring manufacturing enterprise

A Sino-Japanese joint venture with over 40 years of experience in spring manufacturing from its Japanese parent company, it is one of the world's most precise spring manufacturers (wire diameter 0.009mm, equivalent to 1/5 of a human hair).

View More

Corporate Culture

To provide customers with excellent, safe, and environmentally friendly products and comprehensive technical services.

Equipment Display

The company owns more than 90 professional manufacturing equipments and more than 60 testing equipments.

Honorary Qualifications

The company has won many honorary qualifications and passed ISO9001 certification and ISO140001 certification.

Manufacturing Process

Every product is full of technology and know-how, constantly producing products that satisfy customers.

News

Satte Real-time News

Whether it is product consultation, technical support or after-sales service, we will wholeheartedly provide you with professional and timely assistance.

At the same time, we also look forward to working with more partners to make progress together and create a better future.

Always adhere to quality development and continuously improve product services

Sincerely welcome friends from all walks of life to visit and guide

05

/

13

On May 13th, TOSO visited our company for guidance

On May 13th, TOSO visited our company for guidance

07

/

28

Materials and Manufacturing Process of Springs

Springs are widely used in electric tools, such as compression springs for button rebound, tension springs for resetting the cover of electric circular saws, torsion springs for pressing and rebounding switches, spiral springs for carbon brush compression...

01

/

10

Detailed Explanation of Heat Treatment Process Optimization for Spring Steel

Spring steel, as an indispensable material in mechanical engineering, is widely used in the manufacturing of various types of springs, such as automotive suspension springs, industrial equipment springs, precision instrument springs, etc. The performance of spring steel directly determines the service life...